Entering the realm of pellet production can seem daunting at first, but with a thorough understanding of the process, it's an achievable and potentially profitable endeavor. This guide will uncover the key aspects of creating fuel pellets, from raw material selection to the final product. We will as we embark on a journey through the intricacies of pellet making.

- First, understanding the multiple types of pellets and their purposes.

- Subsequently, examine the tools required for efficient pellet production.

- Most importantly,learn the crucial processes involved in transforming raw materials into high-quality pellets.

Pelletizing Technology: Advancements and Applications

Pelletizing technology has witnessed marked advancements in recent years, revolutionizing various industries. These improvements have led to enhanced efficiency, minimized costs, and heightened product quality. One key innovation is the implementation of cutting-edge control systems that allow for precise monitoring of the pelletizing process. This guarantees consistent pellet shape and strength. Furthermore, the integration of novel materials and methods has broadened the scope of pelletizing technology.

Pellets are now employed in check here a wide array of industries, including agriculture, construction, pharmaceuticals, and ecological remediation. In agriculture, pellets serve as optimized delivery systems for fertilizers and insecticides, promoting crop growth and harvest. In the construction industry, pellets are used in the manufacturing of building materials like concrete blocks and bricks, offering durability and cost-effectiveness.

The medical industry leverages pelletizing technology to produce controlled-release drug formulations, ensuring uniform drug delivery over time.

Moreover, in environmental remediation, pellets are employed for the removal of pollutants, contributing to a cleaner and healthier environment.

The continued evolution of pelletizing technology promises even more innovative applications in the future.

Superior Pellets for Manufacturing

In today's dynamic industrial landscape, efficiency and performance are paramount. Manufacturers constantly seek innovative solutions to optimize processes and minimize costs. High-performance pellets have emerged as a essential component in achieving these objectives. These specialized pellets, crafted from carefully selected raw materials, deliver exceptional durability, consistent shape and size, and enhanced chemical properties.

The applications for high-performance pellets are remarkably broad. They find widespread use in industries such as automotive, where stringent requirements are placed on materials. Pellets serve as critical components in the manufacturing of a comprehensive range of products, including machinery parts, contributing to the overall quality of finished goods.

Sustainable Pellet Fuels: Environmentally Friendly Energy

Pellet fuels are a rising choice to conventional fossil fuels. Made from densely packed organic substances like wood residues, pellets offer a renewable source of energy with a minimal environmental impact. Compared to coal or oil, pellet fuels produce less greenhouse gases, contributing to a more sustainable atmosphere. , Furthermore, they are a affordable option for powering homes and businesses.

The Science Behind Pellet Binding and Compression

Pellet binding forms a critical step in the production of high-density pellets for various applications. This method involves compressing finely divided materials, often wood or plastics, into compact cylindrical shapes. The process relies on several physical principles that dictate the stability of the resulting pellets.

One key principle is particle size and distribution. More minute particles tend to compact more tightly, leading to stronger pellets. The degree of compression also plays a major role, as higher pressure yields sturdy pellets with increased resistance.

Furthermore, the type of binder used can materially impact pellet integrity. Binders promote particle adhesion and cohesion, finally resulting in more robust pellets.

Understanding these physical principles is vital for optimizing the pellet binding and compression method, leading to high-quality pellets that meet specific application needs.

Biofuel Pellets: A Renewable Energy Solution

With the global need for energy continually growing, the search for sustainable and renewable energy options is more important than ever. Biofuel pellets, derived from organic biomass materials such as wood residues, are emerging as a viable solution to meet this increasing demand. These compressed pellets serve as a clean and efficient alternative to traditional fossil fuels, offering numerous environmental and economic benefits.

- Created from sustainable biomass resources, biofuel pellets contribute to a circular economy by utilizing otherwise wasted materials.

- Combustion biofuel pellets releases significantly lower air pollutants compared to fossil fuels, helping mitigate climate change.

- The creation of biofuel pellets can create new job opportunities in rural communities and stimulate economic growth.

Amanda Bynes Then & Now!

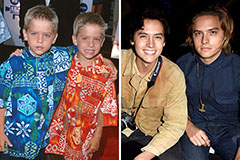

Amanda Bynes Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!